Effective sewer maintenance keeps these billion-dollar systems in proper working order and helps avoid costly damages — but sewer maintenance can come in many different styles. New breakthroughs in modern sewer inspection tools can drastically improve processes, cutting down on time, costs and damage.

From earlier detection to more detailed analyses, advanced technology for sewer maintenance offers a wide range of advantages that allow you to identify and prioritize your most pressing infrastructure issues.

Proactive maintenance solutions aim to identify problems before they balloon into larger issues that might increase complexity, create safety risks or cause more damage and/or costs. In sewer systems, proactive inspection is especially valuable because many problems won’t be visible until they’ve already caused extensive damage. By looking for signs before they appear on the surface, you can intervene earlier and limit the extent of the problem.

For instance, if you see the warning signs of an encroaching tree root, you might be able to patch it up and remove the tree. If you wait for more noticeable signs of damage, you’ll likely pay more to fix significant blockages, replace larger sections of the pipeline and repair any damage.

Other reasons to perform proactive sewer inspections include:

In addition to the technologies we’ll discuss, your local inspection equipment dealer can help with determining maintenance schedules.

A proactive approach often benefits from advanced technology for sewer maintenance. Some common strategies for sewer infrastructure maintenance include:

A visual inspection simply refers to monitoring for any signs of damage that appear aboveground, like sinkholes and flooding. Understandably, these problems typically become severe before you spot them above a pipeline. Visual inspection methods tend to be insufficient for a proactive approach, and they don’t provide any insights into functionality.

Sonar systems emit and measure sound waves to detect any abnormalities in the pipe, such as defects, debris and grease. This technology creates a two-dimensional image of the inside of the pipe. The main benefit of sonar sewer inspections is that they can inspect below the waterline for submerged and semi-submerged pipes.

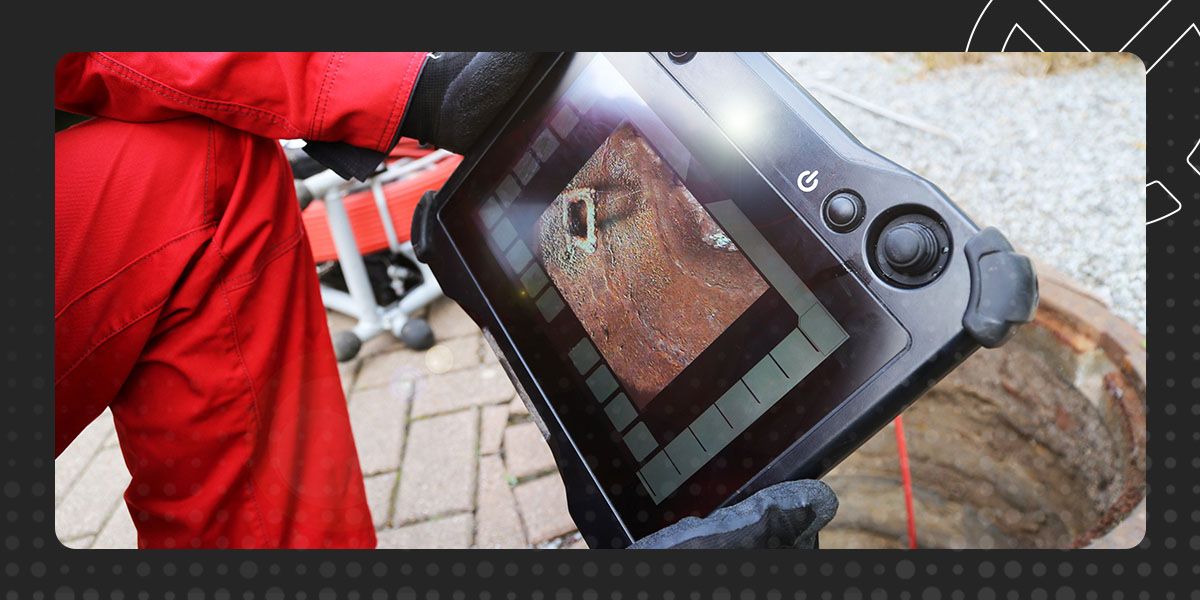

Closed-circuit television (CCTV) technology is a sophisticated piece of inspection equipment that captures video footage of the inside of a pipe. It transmits clear, high-resolution footage in real-time to a certified technician, allowing them to assess the pipe without entering it. CCTV systems work in varying pipe diameters for easier access, and they can precisely identify obstructions, cracks, leaks, corrosion and other problems with pipe conditions.

While a CCTV system is ideal for most sewer inspections, you may need to use it alongside sonar systems if your sewer infrastructure includes submerged or semi-submerged pipes. CCTV sewer cameras cannot provide information below the waterline, and sonar can fill the gap. CCTV is ideal for many other applications, with camera transporters designed for flexibility and outfitted with tools like LED lighting and remote-controlled pan-and-tilt functionality.

Proactive maintenance requires capable software to support your inspection processes. Dedicated maintenance software can facilitate more cost-effective maintenance procedures that minimize disruptions. It can collect and organize inspection data for more informed decision-making and streamlined operations.

For example, the GraniteNet system from Cues offers the following features in an easy-to-use platform to support proactive maintenance strategies:

GraniteNet works alongside Cues camera systems to support a proactive approach to maintenance and help you stay compliant with standards and can integrate with other asset management softwares such as ESRI GIS systems and CityWorks work order systems.

Additionally, some of the larger and more reputable sewer camera manufacturers also offer rehabilitation solutions such as grout trucks, lateral reinstatement cutters, or point repair solutions.

Although CCTV is generally the most versatile option, you’ll still need the right camera for your infrastructure. Cues is an industry leader in sewer inspection equipment, with several options to fit different systems. The Digital Universal Camera (DUC) is a powerful all-around solution suitable for the largest range of pipe diameters available in a digital side-scanning system. It supports diameters from 6 to 60 inches and can provide a full inspection of a 400-foot pipe segment in under 15 minutes.

DUC is an inspection workhorse that can improve inspection speeds and reduce costs. Cues also offers a range of transporters to fit the infrastructure of different sewer systems:

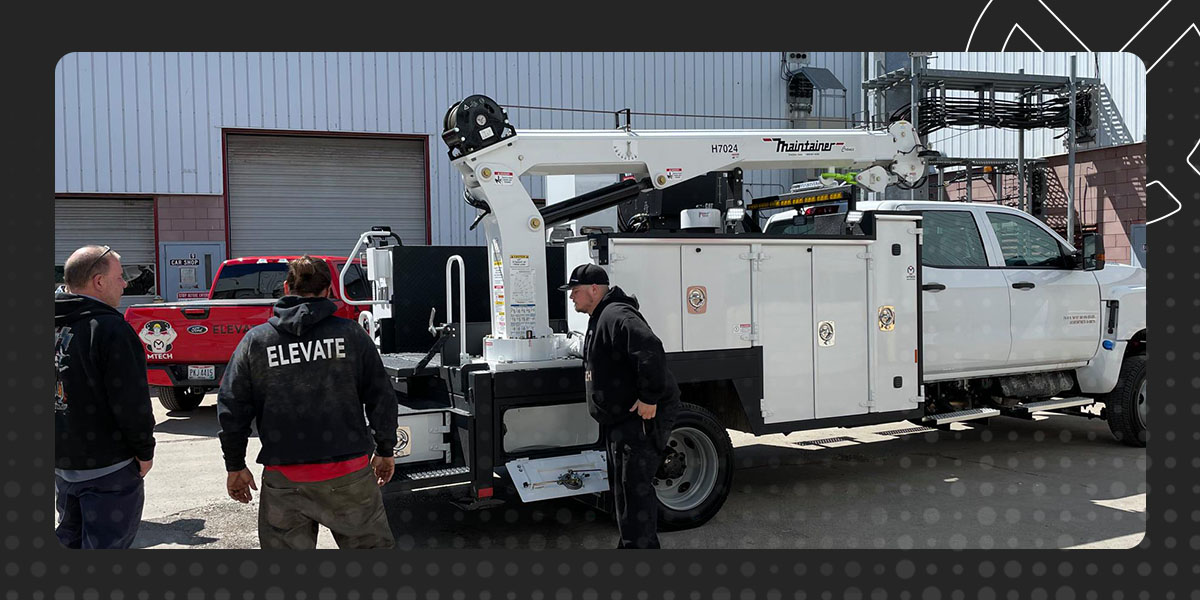

Here at MTech, we’ve been specializing in the sewer industry since 1975. We’re the largest Cues dealer in the world, and our industry expertise makes us a trusted source for businesses and municipalities across Ohio, Michigan and Western Pennsylvania. We pride ourselves on partnering with the top inspection technology brands in the industry, and our knowledgeable team members understand the products inside and out.

While we stay at the forefront of inspection technology, we also know what goes into the job. We understand the importance of sewer line inspection and maintenance from start to finish. When you work with MTech, you work with a dedicated partner in tune with the industry.

Whatever your sewer infrastructure looks like, proactive maintenance can help prevent costly problems and extend the life of pipelines. We’ll work with you to find the right equipment for your infrastructure, budget and goals. Schedule a demo today to see the options for yourself and partner with the sewer inspection professionals at MTech.