This vacuum and jetter truck buying guide will explore everything involved in finding your perfect sewer truck. Contractors, plumbers, maintenance crews, business owners, property managers, government agencies, and municipalities must know how to find the ideal equipment. This guide provides a comprehensive look into what to look for, why it’s important, and suggestions on buying the right sewer truck for your needs.

Factors to Consider When Buying a Sewer Truck

Consider the following when buying a sewer truck:

- Capacity and tank size: Assess the tank capacity to ensure it meets your operational demands. Consider factors like frequency of use, the volume of debris or wastewater generated, and job-site accessibility. Adequate tank size minimizes downtime for emptying and maximizes productivity. It’s also important to differentiate between volumetric capacity (total tank size) and usable capacity (how much of that volume can be effectively utilized). Systems that load from the top rather than the front generally provide more usable capacity, and an ejector system can further enhance this. Additionally, be sure to factor in local weight laws to ensure compliance; exceeding legal weight limits can lead to fines and operational disruptions. Balancing these considerations will help optimize efficiency and regulatory adherence.

- Vacuum and jetting performance: Evaluate the power and efficiency of the vacuuming and jetting system. These two factors directly impact cleaning effectiveness and speed. Opt for robust systems capable of handling various types of debris and blockages. In sewer trucks, the choice between single piston and triplex pumps depends on the specific requirements of the job. Knowing the difference is a crucial part of investing in the right truck. The vacuum system of a sewer truck determines the strength of its suction. Choosing a truck with a positive displacement blower (PDB) or a centrifugal fan can make a big difference.

- Single-Piston Water Pump:

Single-piston pumps boast high volumetric efficiency, achieving over 98%, and operate at the highest hydraulic pressures. This efficiency translates into powerful, consistent performance for sewer trucks, ensuring maximum water transfer and pressure-boosting capabilities. A key advantage is their pressure compensation feature: the pump seamlessly adjusts to match different nozzles’ pressure and flow needs, delivering consistent performance across various tasks. Ease of maintenance is another benefit—if service is needed, the water pump can be rebuilt without removing it from the truck body, reducing downtime and repair costs. Single-piston water pumps provide superior performance and reliability for sewer truck operations, where high hydraulic pressures, volumetric efficiency, and ease of maintenance are essential. - Triplex Water Pump:

Triplex pumps featuring three pistons are often preferred for hydro excavation (HX) trucks operating at lower flows. Their design ensures steady, pulsation-free flow and is well-suited for precision tasks like industrial cleaning. Triplex pumps excel in maintaining consistent high-pressure water delivery in demanding environments, making them ideal for situations where precise flow control is critical. - Positive displacement (PD) blower: As the name suggests, a PD blower uses the principles of positive displacement to create a vacuum by trapping and displacing aircreates vacuum by trapping and displacing air, generating a powerful suction force ideal for removing debris and liquids from sewer lines and catch basins. Unlike centrifugal fans, PD blowers do not require airflow to produce vacuum. This means you can submerge the suction tube underwater and go straight to the blockage without needing to clear the water first—saving time and enhancing efficiency. Key advantages of PD blowers include their high-pressure capabilities and ability to maintain constant suction performance, even as system pressure changes. This makes them exceptionally effective at tackling stubborn sewer blockages and cleaning larger-diameter lines. Additionally, PD blowers offer durable, compact designs with direct-drive options, eliminating the need for belts and pulleys and ensuring reliable and low-maintenance operation.

- Centrifugal fans: Unlike positive displacement blowers, centrifugal fans require air to function and are much louder than a PD blower. They accelerate air radially outward from the impeller’s center, then redirected axially into the vacuum system’s hose or chamber. Centrifugal fans excel at generating high airflow rates and provide strong suction capabilities that are best for dry material and are ideal for catch basin cleaning. It offers variable speed control to control the airflow based on the task.

- Equipment integration: Consider integrating additional equipment that can enhance operation versatility. For example, inspection cameras and auxiliary pumps.

- Vehicle size and maneuverability: Assess the size and maneuverability of the truck to ensure compatibility with job site conditions. Narrow streets, tight spaces, and urban environments should be navigable. A suitably sized vehicle improves accessibility and minimizes logistical challenges during operation. You can find sewer trucks in larger tandem-axel sizes sizes as well as smaller single-axle and non-commercial driver’s license (CDL) trucks.

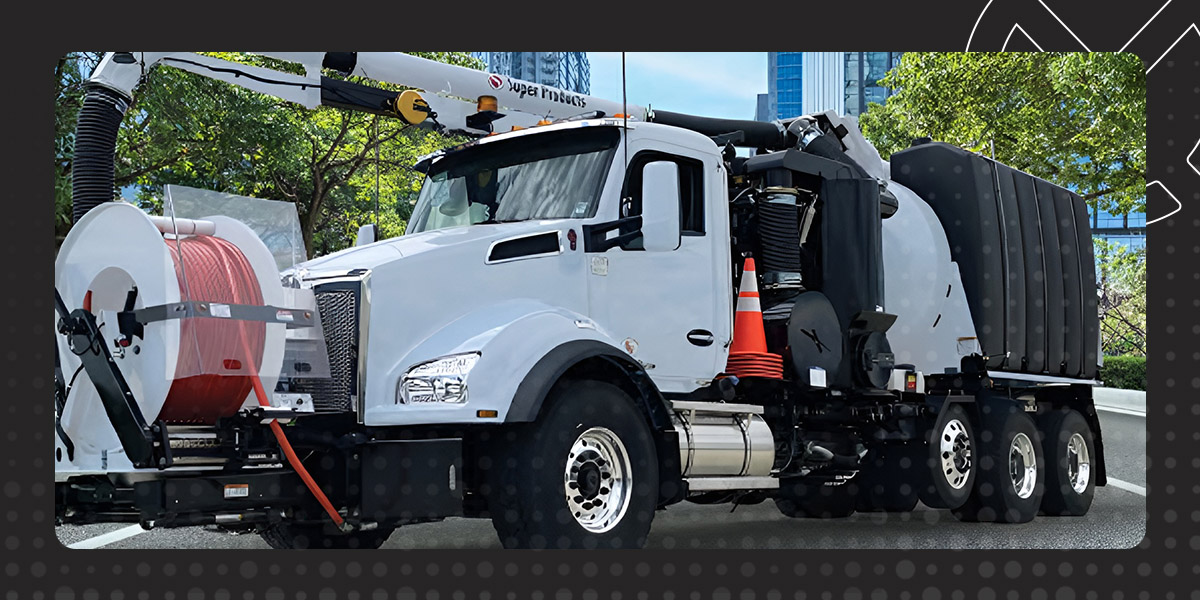

- Tandem-axle: Tandem-axle trucks feature two sets of wheels on each side of the vehicle’s rear axle. This configuration offers increased load-carrying capacity and stability, making it suitable for larger trucks with heavier equipment. Combination vacuum-jetting trucks would benefit from a tandem axle configuration. Trucks with tandem axles can handle more weight without sacrificing maneuverability, making them ideal for demanding sewer maintenance tasks.

- Single-axle: Single-axle trucks have only one set of wheels on each side of the rear axle. While they typically have a lower load-carrying capacity than tandem-axle trucks, they offer greater maneuverability and are often more compact. Single-axle trucks are suitable for smaller vacuum or jetting trucks in urban areas or locations with restricted access.

- Non-CDL: Non-CDL trucks are vehicles that do not require drivers to hold a commercial driver’s license to operate them. These trucks are typically lighter-duty vehicles with smaller tank capabilities and lower gross vehicle weight ratings (CVWR). Non-CDL trucks are often single axles and are suitable for lighter sewer maintenance tasks, such as residential septic tank pumping or small-scale drain cleaning operations.

- Durability and reliability: Prioritize trucks built with durable materials and components. They must withstand the rigors of sewer maintenance operations and guarantee long-term reliability. Investing in quality vacuum trucks and machines is a wise investment in the long run.

- Operator comfort, safety, and efficiency features: Consider the truck’s ergonomic design and safety features. Prioritizing operator comfort mitigates risks during operation. Features like ergonomic controls, visibility enhancements, and safety systems contribute to operator efficiency and well-being. The debris unloading system of a sewer truck is a vital feature to understand as it directly impacts operational efficiency and productivity. Ejector systems and tip-to-dump are two common dumping methods that offer different advantages.

- Ejector systems: These utilize hydraulic power to push debris out of the truck’s tank through a rear-mounted ejector plate. This method allows for quick and efficient unloading without tipping the entire vehicle. Ejector systems specialize in speed and simplicity. Their design enables them to provide rapid turnaround times between jobs and minimize downtime.

- Tip-to-dump methods: Tip-to-dump involves tilting the entire truck’s tank to empty its content. This approach offers versatility, allowing debris unloading in various locations and environments. This approach is advantageous for accessing hard-to-reach areas and ensuring thorough debris removal.

- Fuel efficiency and environmental impact: Evaluate the vehicle’s fuel efficiency and environmental footprint to minimize operational costs.

- Maintenance and Support Services: Evaluate the availability and quality of maintenance and support services to ensure long-term operational reliability. Key factors include access to spare parts, technical assistance, and warranty coverage. Comprehensive support minimizes downtime by enabling prompt repairs and replacements. Additionally, consider the availability of diagnostic tools and services that can quickly identify and address issues, preventing small problems from escalating. Reliable maintenance and diagnostic support ensure optimal performance, extend equipment lifespan, and keep operations running smoothly.

- Cost and budget considerations: Evaluate the total cost of ownership, including purchase price, operating costs and potential financing options. Aligning with budget constraints and financial objectives is vital. Consider long-term value and return on investment (ROI) when assessing cost factors. You might also consider a rent-to-purchase option (RPO), which allows you to test out the equipment you want to buy over an extended period with the option to purchase. If you decide to buy, the sum of your rental payments will be deducted from the total machine price.

- New sewer trucks: Investing in a new sewer truck offers several advantages. They have the latest technology, updated features and warranties that provide peace of mind. New trucks typically come with fewer maintenance issues and may offer improved fuel efficiency and performance. However, they come with a higher upfront cost.

- Used trucks: Opting for a used vacuum truck can be cost-effective. This is especially true for those with budget constraints. While a used truck may have higher mileage and wear and tear, it can still provide a reliable performance with proper maintenance. Additionally, purchasing a used truck may allow for more flexibility regarding available models and features within a given budget.

Understanding Sewer Trucks: Types and Purpose

Understanding the different types of sewer trucks enables municipalities, utility companies, maintenance crews, and contractors to allocate resources to buy the right equipment. This knowledge will ensure that sewer maintenance operations are carried out efficiently by using the correct type of sewer truck for the tasks they are designed to fulfill.

Your choice among these four types of trucks hinges on whether your primary tasks involve heavy-duty clearing, high-pressure cleaning, or straightforward waste suction and transportation.

When considering buying a sewer truck, numerous factors warrant careful examination to ensure optimal investment and operation efficiency. Determine the specific type based on operational requirements. Knowing the selection is crucial as it dictates the vehicle’s capabilities and suitability for intended tasks. Vacuum trucks are suited for debris removal, jetting trucks for high-pressure cleaning, and combination trucks, which offer versatile functionality.

1. Vacuum Sewer Trucks

Using powerful pumps, sewer vacuum trucks specialize in removing debris and liquids from sewer systems. Their efficient vacuuming capabilities streamline maintenance operations, quickly clearing blockages and preventing backups. Access to a vacuum truck allows for faster response times and reduces the risk of sewer system failures. The efficiency and reliability of these trucks make them an indispensable tool.

2. Jetting Sewer Trucks

Jetting sewer trucks use high-pressure water pumps to effectively clear obstructions and debris from sewer lines. The precision and forceful jets of a sewer jetter ensure thorough cleaning, preventing blockages and minimizing the risk of backups. Owning a sewer jetter truck provides benefits like efficient line clearing, enhanced sewer system performance, and reduced maintenance costs.

3. Combination Sewer Trucks

Combination sewer trucks perform multifaceted tasks essential for sewer maintenance. Equipped with powerful vacuum pumps and high-pressure water jetter systems, they efficiently remove debris and flush obstructions from pipelines. These versatile vehicles streamline operations, minimizing the need for multiple pieces of specialized equipment. Their ability to tackle various challenges ensures optimal sewer system functionality.

In addition to sewer cleaning, many combination trucks can perform hydro excavation—an innovative, non-destructive digging method. By using high-pressure water to break up soil and a vacuum system to remove the slurry, hydro excavation exposes underground utilities safely and precisely. This capability is particularly beneficial for utility locating, trenching, and daylighting, reducing the risk of damage to existing infrastructure compared to traditional digging methods.

Combination sewer cleaners enhance operational efficiency, prolong infrastructure lifespan, and mitigate risks. Their dual functionality in sewer maintenance and hydro excavation makes them indispensable for municipalities and contractors, offering cost-effective solutions for complex underground projects

4. Septic Trucks

Septic trucks are purpose-built vehicles designed to maintain and service septic systems. Equipped with powerful vacuum pumps, these trucks effectively remove solid waste, sludge, and liquids from septic tanks. They clean empty tanks by creating suction and preventing overflow and system failures. The benefits of owning a septic truck include reliable waste removal, ensuring proper system functionality, and reducing the risk of environmental contamination.

Get Premium Products and Superior Service When You Partner With MTech

MTech has been a part of the sewer, street and safety industries since 1975 and we use our experience to provide value to customers as a full circle partner and give meaningful advice. Our comprehensive selection of premium sewer trucks, including Super Products and PipeHunter, with the guidance of MTech consultants, allows businesses, maintenance crews, contractors, and more to find the perfect truck for their needs.

At MTech, we are dedicated to being your partner in success, going beyond just a sale. We carefully select manufacturers who share our commitment to excellence, ensuring that you receive only the best. Our network of trusted advisers and consultants is here to guide you in making well-informed purchasing decisions, offering unbiased expertise and ongoing communication with regional sales managers throughout the entire process.

When you choose MTech, you gain more than just a product – you gain access to our comprehensive on-site and 24/7 support services offer a huge benefit. If your equipment encounters any issues, our factory-certified technicians and fully stocked parts inventory are ready to minimize downtime with prompt repairs. We take pride in delivering swift, reliable service for all the original equipment manufacturers we carry, ensuring your operations run smoothly. Partnering with MTech goes far beyond the initial purchase.

Contact us to learn more about our purchasing options or to schedule a demo.